Partnership of Lean Six Sigma and Digital Twin under Type 2 Neutrosophic Mystery Toward Virtual Manufacturing Environment: Real Scenario Application

Main Article Content

Abstract

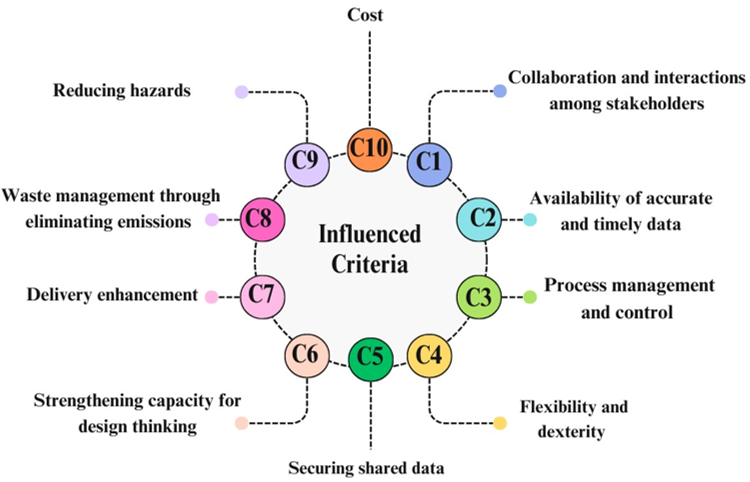

The correlation between Lean Six Sigma performance strategy (LSS) and contemporary innovations, including Digital Twin (DT) technology (DLSS) has been scrutinized in this study. The merger's mission is to overcome some of the organizational tensions. Environmentally speaking, it's critical to cut waste and save resources. On a social level, demonstrated boosts to labor and machine efficiency through scrutinizing analysis, simulation, and virtual-physical replication. Economically speaking, improved quality, lower prices and lead times, continuous improvement, and performance enhancement techniques are all part of the worldwide manufacturing scene. Actually, harnessing the suitable DT application amongst available applications is a noteworthy procedure. Hence, this study evaluates DT applications by constructing a decision framework. The constructed framework depends on decision methodologies of multi-criteria decision-making framework (MCDM) and the vague theory of type 2 neutrosophic sets (T2NSs). The entropy and Complex Proportional Assessment (COPRAS) of MCDM are working in cooperation with T2NSs to recommend optimal DT application which merges with LSS toward sustainability of the organization's industrial.

Downloads

Article Details

This work is licensed under a Creative Commons Attribution 4.0 International License.