A Novel Deep Learning Model for Tool Wear Estimation of Cutting Tools

Main Article Content

Abstract

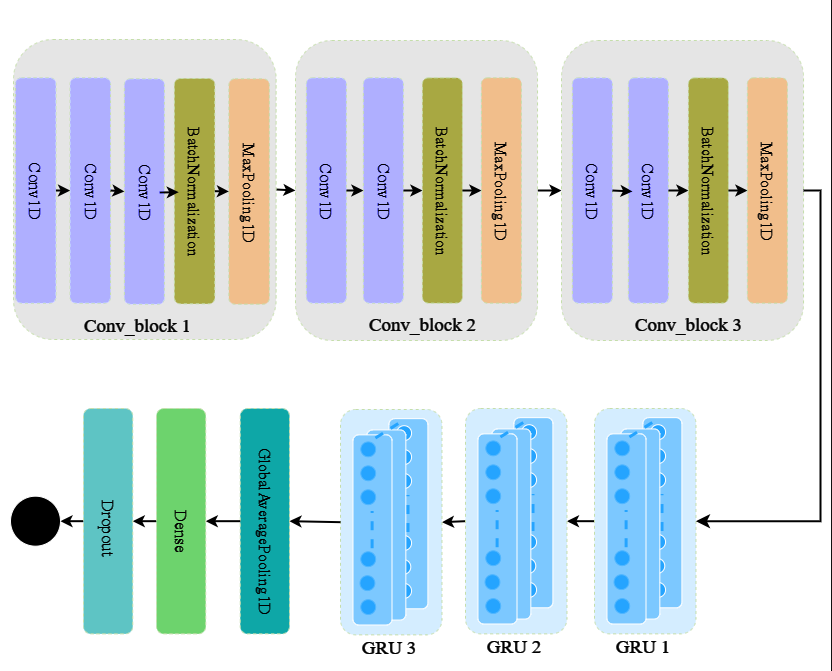

In cutting tools, tool wear may result in low-quality surfaces and precision in dimensional measurement. Tool wear may additionally result in fractures and harm to the workpieces over operations. It's critical to track tool wear in life in order to avoid these situations. This research proposes a data-driven deep learning strategy to improve the accuracy of cutting tool wear estimates. This technique combines a Gated Recurrent Unit (GRU) with a Convolutional Neural Network (CNN). In order to circumvent the problems associated with single-domain features that lack appropriate tool status data, a multi-domain combination technique was used to develop candidate features. We retrieved 4 frequency-domain features, 8 time-frequency domain features, and 12 time-domain features from each channel signal. The CNN eliminates the need for human feature extraction by automatically identifying significant attributes from raw time series data. The model is able to generate more abstract data representations and understand complex temporal patterns thanks to the GRU. Using the dataset of the 2010 PHM Data Challenge, comparisons with a number of deep learning models were conducted in order to show the effectiveness of the suggested model. The results of the studies indicate that CNN-GRU is a good option for estimating the tool wear of cutting tools because it outperformed all other models that were looked at.

Downloads

Article Details

This work is licensed under a Creative Commons Attribution 4.0 International License.